راتنج إيبوكسي سائل رباعي الوظائف مقاوم لدرجات الحرارة العالية YLSE-721

Nov 13, 2025

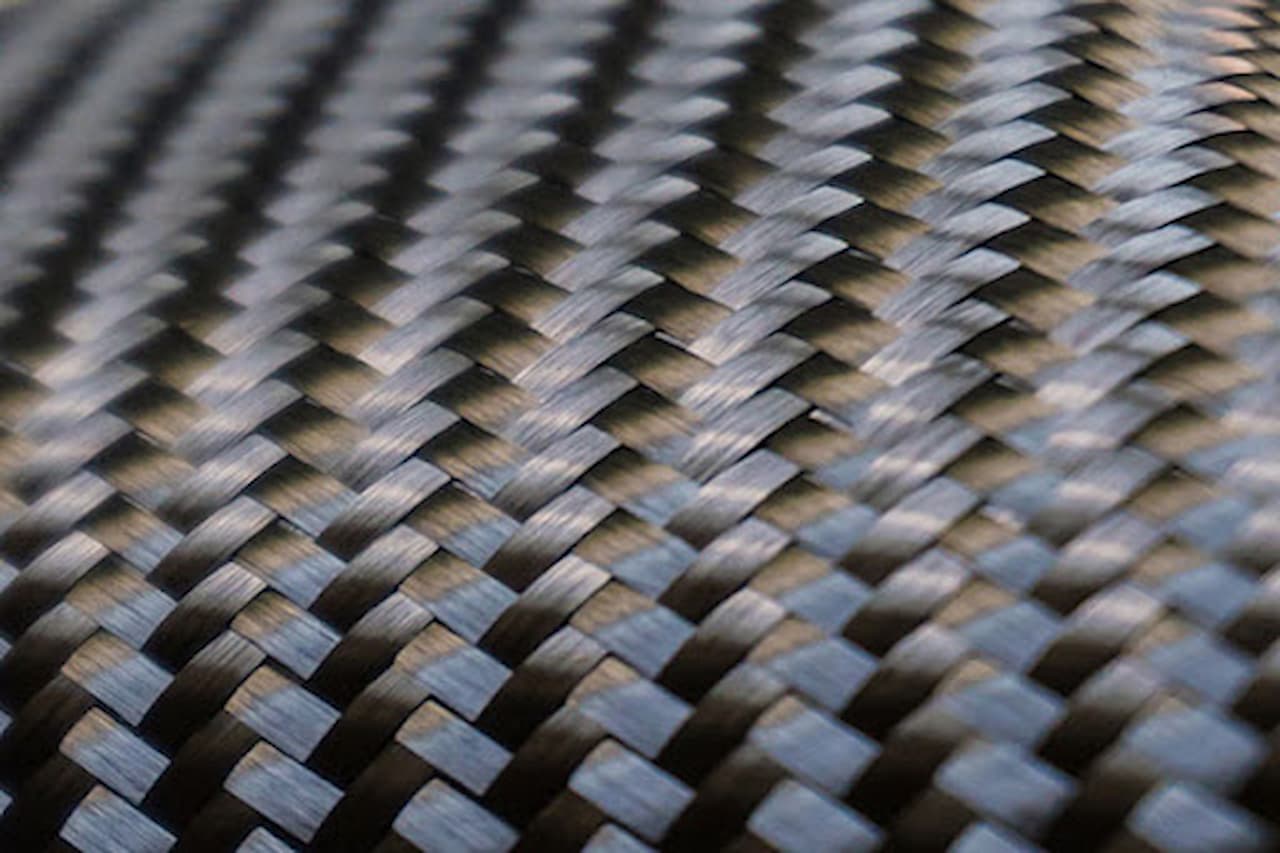

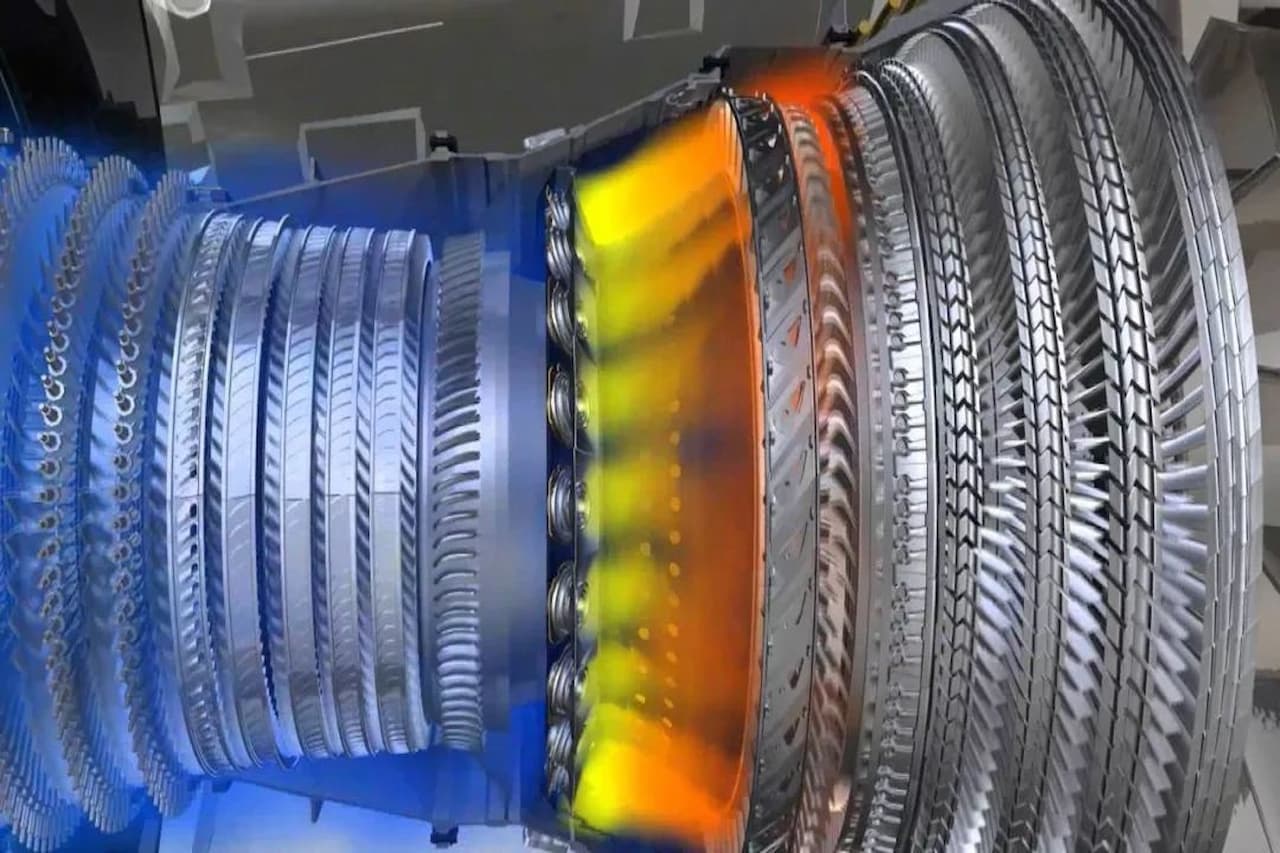

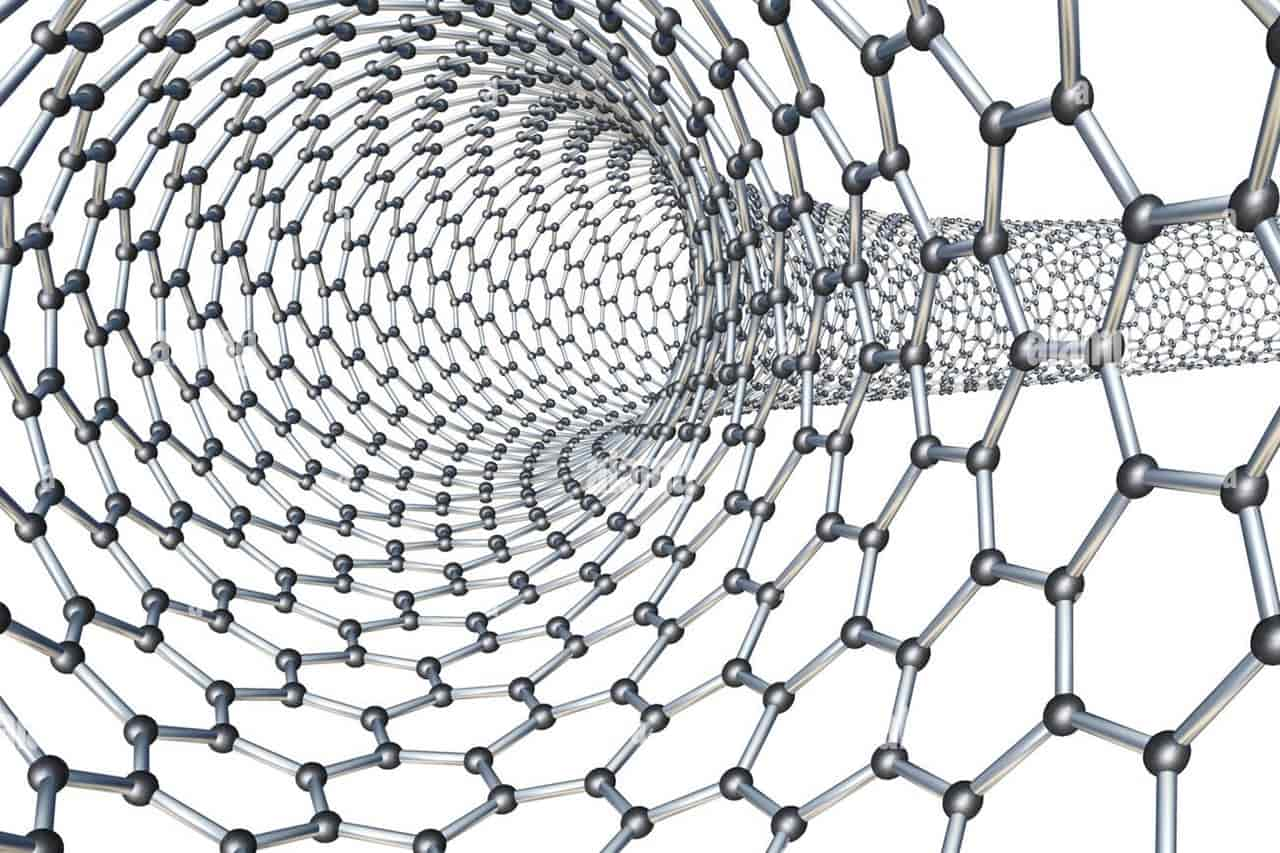

لماذا يُعدّ YLSE-721 منتجنا الرائد؟ ما الذي يجعله "مُميّزًا" لهذه الدرجة؟ YLSE-721 هو عبارة عن راتينج إيبوكسي سائل عالي الأداء رباعي الوظائف يعتمد على الأمينو - وهو "مادة رابطة رئيسية صناعية" مصممة خصيصًا للتطبيقات عالية القوة ومقاومة للحرارة العالية.يكشف اسمه عن السر: "رباعي الوظائف" يعني أن كل جزيء يحتوي على أربعة مواقع تفاعلية، كـ"محارب متعدد الأذرع" قادر على تكوين شبكة متشابكة أكثر كثافة وقوة مع عوامل المعالجة. وهذا هو السبب الرئيسي وراء تفوق قوته بكثير على راتنجات الإيبوكسي ثنائية الوظائف العادية. وفي الوقت نفسه، يوفر شكله السائل سيولة ممتازة، مما يجعله مثاليًا للتغليف أو الطلاء أو ملء الهياكل المعقدة، مما يضمن سهولة وفعالية الاستخدام.ما يثير إعجاب المستخدمين حقًا هو "ثلاث ميزات": مقاومة درجات الحرارة العالية، والتصلب السريع، والقوة الميكانيكية الفائقة. مقاومة للحرارة: تتحمل درجات حرارة تصل إلى ١٥٠ درجة مئوية، وتتحمل درجات حرارة أعلى من ١٨٠ درجة مئوية لفترة قصيرة، متفوقةً بذلك على الإيبوكسي القياسي (عادةً ١٢٠ درجة مئوية أو أقل). مثالية لمحيط المحرك، وملفات المحرك، وحماية لوحات الدوائر المطبوعة (PCB) في درجات الحرارة العالية. 🔧 سرعة المعالجة: تتصلب بالكامل خلال 30-60 دقيقة عند درجة حرارة تتراوح بين 60-80 درجة مئوية، وهي أسرع بمرتين إلى ثلاث مرات من أنظمة الإيبوكسي التقليدية - مما يوفر الوقت بشكل حقيقي للمشاريع العاجلة. الخصائص الميكانيكية: تتجاوز قوة الشد 50 ميجا باسكال، وقوة الانحناء 80 ميجا باسكال، مع مقاومة ممتازة للصدمات وثبات أبعادي. كما أنها مقاومة للتشقق حتى في ظل الاهتزازات الشديدة أو الدورات الحرارية. فضلاً عن ذلك، YLSE-721 تقدم عزلًا كهربائيًا متميزًا ومقاومة للزيت ومقاومة للماء ومتانة كيميائية - مما يجعلها تستحق حقًا سمعتها باعتبارها "الرجل الحديدي في العالم الصناعي". معلومات المنتج الاسم الكيميائي: N,N,N',N'-تتراجليسيديل-4,4'-دايامينوديفينيل ميثانرقم CAS: 28768-32-3الصيغة الهيكلية التطبيقات الرئيسية المواد المركبة المقاومة لدرجات الحرارة العالية مثل ألياف الكربون والألياف الزجاجية؛ تعبئة المكونات الإلكترونية (مثل وحدات الطاقة، وبرامج تشغيل LED)؛ حماية التشريب والعزل للمحركات وملفات المحولات؛ تصنيع القوالب الدقيقة، بما في ذلك ربط المعادن والسيراميك والمركبات؛ ربط وختم المكونات الهيكلية للطائرات الفضائية؛ طلاءات مقاومة للتآكل وإصلاح الأجزاء الميكانيكية الثقيلة. تعليمات الاستخدام يمكن صياغة YLSE-721 باستخدام عوامل معالجة وعوامل ربط من النوع الأميني أو الأنهيدريدي أو الإيميدازولي لإعداد المواد اللاصقة أو مركبات الصب أو الأنظمة المركبة للتطبيقات التي تتطلب مقاومة ممتازة للحرارة. تشمل عوامل المعالجة الشائعة 4,4'- ثنائي أمينو ثنائي فينيل سلفون (4,4'-DDS)، و4,4'- ثنائي أمينو ثنائي فينيل ميثان (DDM)، وأنهيدريد ميثيل رباعي هيدروفثاليك (METHPA)، وأنهيدريد ميثيل نادك (MNA)، و2-إيثيل-4-ميثيل إيميدازول (2,4EMI).إذا بدا الراتنج لزجًا جدًا أثناء الاستخدام، فيمكن تسخينه إلى درجة حرارة مناسبة لتقليل اللزوجة قبل الخلط. لتحسين الصلابة، يمكن دمج إضافات مثل مطاط البولي سلفيد السائل أو مطاط النتريل السائل. خصائص المعالجة النموذجيةدكتور جراحة الأسناندي دي إمميثباوكالة أنباء الشرق الأوسططريقة الاختباردرجة حرارة انتقال الزجاج (°م)250-260220-230200-210235-240قوة الشد (ميجا باسكال)75505045معامل الشد (جيجا باسكال)3.53.33.23.6قوة الانحناء (ميجا باسكال)13012010097معامل الانثناء (جيجا باسكال)3.33.44.03.8الاستطالة عند الكسر (%)2.81.61.91.1قوة التأثير (كيلوجول/م²)151098نسبة الراتنج إلى المصلب (بالوزن)100:52100:42100:42100:150جدول المعالجة100 درجة مئوية * 2 ساعة + 130 درجة مئوية * 2 ساعة + 160 درجة مئوية * 2 ساعة + 180 درجة مئوية * 2 ساعة + 200 درجة مئوية * 2 ساعة الأخطاء الشائعة التي يجب تجنبها ❌ مزيج غير صحيح من عوامل المعالجة: يجب استخدام YLSE-721 مع عوامل معالجة أنهيدريدية أو أمينية عطرية محددة. قد يؤدي استخدام مُصلِّبات إيبوكسي عامة إلى معالجة غير كاملة، أو ملمس طري، أو انخفاض كبير في مقاومة الحرارة. ⚠️ ❌إهمال تحضير السطح: يجب تنظيف الركيزة جيدًا وتجفيفها ورملها؛ وإلا فقد يحدث فشل في الالتصاق أو "ارتباط كاذب". ❌ ارتفاع درجة الحرارة أثناء المعالجة: على الرغم من أن الراتنج يتمتع بمقاومة حرارية عالية، يجب الحفاظ على المعالجة ضمن نطاق درجة الحرارة الموصى به (عادةً من ٦٠ إلى ١٢٠ درجة مئوية). قد تؤدي درجة الحرارة الزائدة إلى ظهور فقاعات أو تغير اللون. احتياطات بسبب وظيفتها العالية وقيمتها الإيبوكسي، تطلق YLSE-721 كمية كبيرة من الحرارة أثناء المعالجة، لذا يجب اتخاذ الاحتياطات اللازمة لمنع البلمرة الجامحة. إذا كانت اللزوجة عالية جدًا بحيث لا يمكن استخدامها بشكل مريح، قم بتسخين الراتنج إلى 100–120 درجة مئوية لمدة ساعة تقريبًا لتقليل اللزوجة. ⚠️ عند التسخين، أبقِ غطاء الحاوية مفتوحًا لمنع انفجار البلمرة. هذا الراتنج الإيبوكسي مقاوم للقلويات ولكنه غير مقاوم للأحماض القوية.

إقرأ المزيد